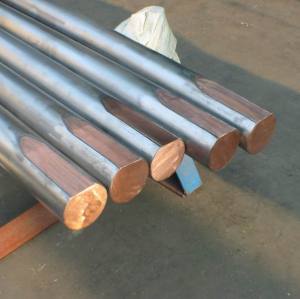

Titanium clad copper machining porous parts

- Model

- 103*13*1950mm*drawing (Ti thickness:1.0mm)

Item specifics

- Ti:Gr2

- Cu:C11000

- Strong corrosion resistance

- Electrical conductivity is strong

- Long use life

- Electroplating Industry

Review

Description

TitaniumCopper Composite Bar Productio

Our company production of Titanium Copper Composite Barimplement national standards GB/T12769-2003, production technology extrusion andhot rolling technology process.

Extrusion process: put the base material copper bar and thecomposite material titanium tube set together,after extrusionprocess, make the copper bar and the titanium tube preliminary compositetogether,formation of titanium copper billet material.

Hot rolling process technology: put the titanium copper billet materialinto the hole pattern rolling mill, hot rolled into required size, make thetitanium and copper reach the certain composite strength. Then straightening, surfacetreatment processes such as, eventually become a finished product.

Detection means for titanium copper composite bar: Ultrasonic flawdetection, inspection titanium copper composite bar joint.

Penetration testing, inspection titaniumcopper composite bar

welding conditions.